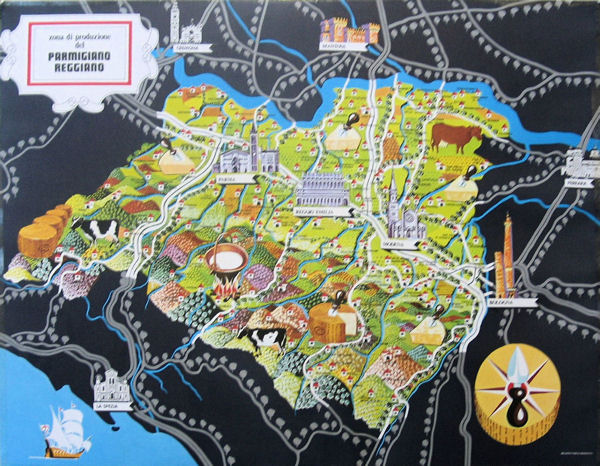

Parmigiano-Reggiano is a hard, granular cheese, named after the producing areas of Parma and Reggio Emilia,

in Emilia-Romagna, Italy. We visited one of the farms where this cheese is produced.

The cheese is made in a number of steps. Morning milk is mixed with skim milk from the previous evening's

production, producing a partly skimmed milk.

The mixture is mixed with natural whey and calf rennet, used to thicken the liquid, and then loaded into vats.

The vats each hold 1100 liters of liquid.

The liquid goes through a cooking process for about 15 minutes and then a sedimentation process for an hour.

Each vat produces two cheeses weighing in at about 45 kg. These are retrieved from the vats using a sort

of cheese cloth.

Click

here and

here to see videos.

The cheese is put into a stainless steel round form that is pulled tight with a spring powered buckle

so the cheese retains it wheel shape. After a day or two, the buckle is released and a plastic belt

imprinted numerous times with the Parmigiano Reggiano name, the plant's number, and month and year of

production is put around the cheese and the metal form is buckled tight again.

The imprints take hold on the rind of the cheese in about a day and the wheel is then put into a brine

bath to absorb salt for 20 days.

After brining, the wheels are then transferred to the aging rooms in the plant for 12 months. Each cheese is

placed on wooden shelves that can be 24 cheeses high by 90 cheeses long or about 4,000 total wheels per aisle.

Each cheese and the shelf underneath it is then cleaned robotically every 7 days. The cheese is also turned at

this time.

At 12 months the Consorzio Parmigiano Reggiano inspects each and every cheese. The cheese is tested by a

Master grader whose only instruments are a hammer and sound. By tapping the wheel at various points, he can

identify undesirable cracks and voids within the wheel. Those cheeses that pass the test are then heat

branded on the rind with the Consorzio's logo. Cheeses that are not so selected have their rinds

remarked with lines or the letter x all the way around so consumers know they are not getting top quality

Parmigiano Reggiano.

Click

here to see a video.

Next we visited Acetaia Malpghi in the Modena area, which is a family business that produces Balsamic vinegar.

Balsamic vinegar is manufactured from the juice of white grapes boiled down to approximately 50% of its original

volume to create a concentrated must, which is then fermented with a slow aging process which concentrates the

flavours.

The flavour intensifies over decades, with the vinegar being kept in fine wooden casks, becoming sweet,

viscous and very concentrated. The finest and most traditional balsamic vinegar is very

labour-intensive to produce; while it ages and gradually evaporates, the liquid is transferred to

successively smaller casks made of different woods, absorbing the flavour characteristics of each

wood and becoming more concentrated with each transfer. Oak, mulberry, chestnut, cherry, juniper,

ash, and acacia are the most commonly used woods

Here is a sample of some of the Balsamic Vinegars produced here.